Welcome to SN METALLICS Precitech Pvt. Ltd

Where your TOTAL PEACE OF MIND is our ultimate measure of SUCCESS

We transform ideas into precision-engineered solutions with Our manufacturing excellence, timely deliveries, and unmatched quality, that provide the backbone support to a diverse range of industries, from Building and Construction, Telecommunication, Lightning to Hydraulics, Earthmoving, Oil-Gas, and beyond

Optimizing the 100% advantages of latest Turning/Milling Centres is what we are known for.

From drawing, designing and programming to the finest finish, Accuracy and Quality, our machining experts and development professionals bring the exact component out of drawings, our customer sent.

We are producing 6 million components in a year and are aiming to double our strength by 2025.

Our advanced state-of-the-art in-house pressure die casting facilities allow us to produce high-quality, precision-engineered components that meet the stringent requirements of various industries.

With state-of-the-art stamping presses and advanced tooling, we deliver high-quality stamped components that are tailored to meet the exacting demands of industries worldwide. Our expertise spans a wide range of metals, including steel, aluminium, brass, and specialised alloys, ensuring flexibility and excellence across diverse applications. Whether it’s high-volume production or intricate, complex parts, every press is engineered for accuracy, consistency, and durability.

With our expertise in investment casting, we ensure that every pour results in components that are both reliable and robust, ready to perform under the most challenging conditions.

Our state-of-the-art foundry is equipped with advanced melting, molding, and finishing technologies, ensuring every casting meets the highest standards of quality, durability, and accuracy. From automotive to industrial machinery, we serve a diverse range of industries, delivering casting solutions that are both cost-effective and timely.

We shape metals with world class Forging hammers capable of stroking up to 100 kg in a single piece. Whether it’s hot forging, cold forging or screw pressing, we put the experienced and technically proven hands together on each stroke to enhance the accuracy of each component forged. Using automatic heating induction to normalising facilities, we use internationally recognized machineries only.

The experience of our forge masters is more than just a number, we have developed more than five hundred critical lines of components within our facilities and are continuously striving to get more innovative jobs.

Our design and development team is at the forefront of innovation, turning complex ideas into functional, high-performance Components that drive industries forward. Leveraging advanced CAD/CAM systems, 3D modelling, and simulation software, we meticulously design every component to optimise performance, durability, and cost-efficiency. Whether you need rapid prototyping, reverse engineering, or intricate mould designs, our expert engineers and technicians ensure that every solution is crafted with precision, right from concept to final production.

With a legacy of over 500 successfully developed critical components, and a continuous drive for excellence, we push the boundaries of what’s possible.

Millions of Components, A Single Vision

Automotive Components

We Manufacture high-quality components for the automotive industry, including aftermarket parts, heavy vehicle components, and engine assemblies. With a focus on reliability and precision, we are ready to support and enhance the standards of today’s automotive manufacturers.

Capacity for High Volume Production : Capable of meeting the demands of large-scale OEMs and aftermarket distributors.

Advanced Manufacturing Standards : Utilizing cutting-edge forging, casting, and machining technologies.

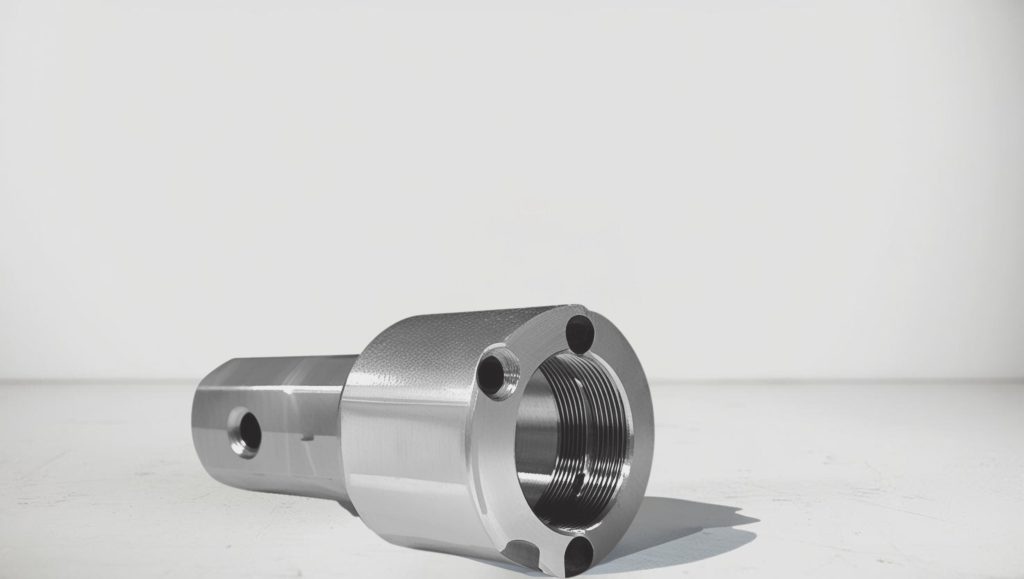

Hydraulic Components

We manufacture Range of High-Performing precision-engineered components from the series of hydraulic Cylinders including cylinders Ears, Heads, Gland, Pistons, Rod Ends, Flange to the pumps, valves, and a range of fluid power applications.

Precision Tolerances : Ensuring optimal performance and seamless system integration.

State-of-the-Art Production : Incorporating advanced forging, casting, and machining processes to meet the highest industry standards.

Oil & Gas Components

we supply a broad range critical oil and gas applications. Our advanced manufacturing capabilities ensure that each component delivers maximum strength and precision tolerances for seamless integration into your equipment.

Customised Solutions : Tailored to fit unique specifications, meeting industry regulations and operational requirements.

Rigorous Testing & Quality Control : ISO 9001:2015 accredited, guaranteeing consistent reliability in the most challenging conditions.

Earthmoving and Agriculture

We manufacture rotor hubs and generator housings to flanges and nacelle components for the Earthmoving and In agriculture From gear housings and transmission parts to engine components and attachments.

High-Strength Alloys : Built to resist wear, corrosion, and fatigue in extreme weather conditions.

Custom Solutions : Tailored parts designed to meet the unique requirements of each project.

Motors, Pump and Valves Components

From Shafts and rotors, to impellers, casings, and housings, We serve as the backbone of pump, valve, and motor systems. Our high-quality parts are built to withstand extreme pressures, resist corrosion, and deliver exceptional durability.

Customised Solutions : Tailored to fit specific pump, valve, and motor designs, meeting unique operational needs.

Building ware components

Our range of metal components for building ware is engineered to offer unparalleled strength, resilience, and longevity, from steel beams, metal studs, and rebar to joist hangers, brackets, and anchors, Fasteners and Connectors crafted for secure connections, engineered to provide reliable solutions, each component is crafted to endure the demanding environments of modern construction while providing structural stability and support.

Our Value Added Services

Processed Raw Materials and Treatments

With a commitment to material excellence, we supply high-grade, processed raw materials tailored for specific uses across sectors like hydraulics, and power generation. Our treatments, including heat treatment, corrosion resistance coatings, and hardening processes, ensure that every material performs reliably under the most demanding conditions, extending the lifecycle and durability of each component.

In-House Product Development

With a specialised focus on custom and high-precision components, our product development team works closely with clients to create innovative solutions tailored to their specific applications. From prototyping and design testing to quality assurance, we ensure each product not only meets but exceeds technical and performance requirements, streamlining development cycles and reducing time-to-market.

Inventory Management / Warehousing

Our flexible inventory management services provide efficient storage solutions, ensuring that critical components are always on hand. We offer customized warehousing plans, dedicated space for high-priority items, and just-in-time delivery options, helping clients control costs, manage stock, and keep projects on schedule—especially vital in industries like automotive, oil & gas.

Research & Development (R&D)

Our R&D department is dedicated to pushing the envelope in material science, design optimization, and manufacturing technology. We regularly collaborate with clients to explore enhancements, find cost-saving alternatives, and advance component quality. With the latest lab and testing facilities, our R&D team is at the forefront of engineering excellence, providing our clients with next-generation solutions.

Technical Support

At SN Metallics, we pride ourselves on proactive technical support for seamless integration and product performance. Our expert technicians are available for detailed product consultations, custom specifications guidance, and on-demand troubleshooting. Whether adapting existing designs or creating a new component, our support team ensures every project proceeds smoothly from concept to completion.

Logistics Support

Our logistics team manages global shipping and customs to simplify and expedite delivery processes for our clients. By integrating advanced tracking and warehousing solutions, we ensure that every component arrives safely, on time, and in pristine condition. We support complex international logistics needs, serving regions across the Americas, Europe, Oceania, and Asia with reliable and economical shipping solutions.

Aftersales Support

Our relationship with clients extends beyond the sale, providing ongoing maintenance guidance, replacement support, and technical follow-ups. We’re committed to helping clients maximize the operational life of each component, offering proactive service that keeps equipment running at peak performance, minimizing downtime and maximizing return on investment.

Quality

Every single Component, Every single Process, Every single stage Quality is an excellence of SN metallics. From the moment raw materials enter our facility to the final inspection and packaging, we’re hands-on with each process, each stage, ensuring that nothing slips through the cracks. Our quality control team isn’t just skilled they’re passionate about what they do. They inspect each piece with the same dedication they would bring to building a part for their own families.

We don't compromise because, at SN Metallics, we know our customers are relying on us for the best, and we hold ourselves accountable to that trust. It’s this dedication to personal excellence in quality that makes our work a true reflection of who we are.

Global Support and Supply Chain Solutions

Our commitment to timely delivery and dependable support drives our operations across multiple continents, ensuring every client, regardless of location, receives their components on schedule. From North America and Europe to Oceania, we prioritize the urgency of each project, meeting deadlines with precision and efficiency.

With our dedicated logistics team, we handle every step from secure packaging and documentation to real-time tracking ensuring smooth, reliable delivery,

Fastest Air Delivery

7-day shipping to any corner of the world by air.

Dependable Sea Shipping

Maximum 45-day delivery for global destinations by sea.

This capability enables us to meet the demands of dynamic industries while giving clients peace of mind in knowing their components will arrive when they need them. Our global supply chain is streamlined, resilient, and ready to support your business no matter where you are.

Our end-to-end supply chain solutions include strategic warehousing, efficient inventory management, and streamlined logistics, optimised to reduce lead times, cut costs, and mitigate supply disruptions. With dedicated hubs across the U.S., Europe, Oceania, and other key regions, we’re able to respond swiftly to client demands and manage the complexities of international regulations and customs processes.

What Sets Our Global Support Apart

Our strategically located 3PL warehouses

Our strategically located warehouses allow for localised inventory, ensuring that products are available close to client locations. This helps reduce lead times, enabling faster response to urgent demands while minimizing logistics costs

On-Site Support: Rapid Response, Wherever You Are

Through trusted collaborations with service providers worldwide, SN Metallics ensures reliable support for our customers, no matter their location. Whether it’s assistance with warehousing, addressing delivery delays, or managing manufacturing issues, our team is prepared to step in with solutions that prevent disruptions. We’re committed to resolving challenges before they impact your operations, ensuring smooth, reliable service from delivery to deployment.

Just-in-Time (JIT) Inventory

Our JIT inventory solutions ensure clients receive their products precisely when needed, maximizing efficiency and reducing the need for onsite storage. This model provides clients with flexible, on-demand access to components, supported by our advanced inventory tracking.

Advanced Logistics Network

Our partnerships with leading logistics providers enable us to manage multimodal transportation options, including air, sea, and land, ensuring reliable, cost-effective shipping. We utilize real-time tracking and proactive communication to keep clients informed at every stage.

Case study

At SN METALLICS, we promise efficiency in all aspects of development, manufacturing, process optimisation, and supply chain management,by innovating, adapting, and optimising our offerings with every project that we undertake.

Explore Few of our projects in depth and understand that when we say that we have solutions for every requirement, we mean it.

Our JIT inventory solutions ensure clients receive their products precisely when needed, maximizing efficiency and reducing the need for onsite storage...

A Leading manufacturer of Hydraulics Equipments was looking for a machine shop that was willing to invest in new capacity to help them meet their growth targets...

A global Oil & Gas company contacted to make hundreds of thousands of Valve bodies and fittings each year...

Due to concerns regarding proper quality and regular supply...

Core competence

Consistency and Adaptability

With in-house forging, casting, machining, and pressure die casting facilities, we offer a comprehensive suite of production processes under one roof. This integration allows for consistent quality control, streamlined production, and adaptability to complex design requirements across multiple industries.

Precision Engineering and Customization

Our team is skilled in transforming technical drawings and intricate designs into perfectly crafted components. We work closely with clients to develop custom solutions that meet exacting standards, whether for automotive, oil and gas, or hydraulic applications.

Quality Assurance Excellence

Certified under ISO 9001:2015 and equipped with state-of-the-art testing facilities, SN Metallics prioritizes quality at every stage. Our rigorous testing protocolsincluding material verification, dimensional accuracy, and performance testing ensure that every component meets or exceeds industry standards.

Global Supply Chain and On-Site Support

Serving clients across North America, Europe, Oceania, and beyond, we provide seamless logistics support, from warehousing to on-site assistance. Our local partnerships and dedicated service network ensure quick response times, reducing downtime and maintaining operational continuity.

Commitment to Innovation and Sustainability

SN Metallics is dedicated to continual improvement and sustainable practices. We invest in advanced technologies and material science to develop lighter, stronger, and more efficient components that support the evolving needs of our clients and contribute to a sustainable future.

Experienced Workforce and Technological Expertise

Our team of technocrats, engineers, and quality specialists brings a wealth of experience, innovation, and precision to every project. We continuously refine our processes and capabilities to align with the latest industry standards, ensuring we remain a trusted partner for our global clientele.